Product Search

Grinding Equipments

Home > Products > Grinding Equipments

Raymond Mill

Raymond Mill is suitable for making powder equipment at high closed circuit circle from all kinds of mine, chemical industry, building material, metallurgy. It can mill quartz, feldspar, calcite, talc, barite, fluorite, rare-earth, marble, ceramic, bauxite, manganese ore, iron mine, copper, phosphate

We're here to help

Easy ways to get the answers you need.

Contact Now

- TEL:0086-21-68406143-802

- FAX:0086-21- 68406146

- Email:[email protected]

Raymond Mill is suitable for making powder equipment at high closed circuit circle from all kinds of mine, chemical industry, building material, metallurgy. It can mill quartz, feldspar, calcite, talc, barite, fluorite, rare-earth, marble, ceramic, bauxite, manganese ore, iron mine, copper, phosphate ore, etc, whose Moh’s hardness less than 7 degree and the moisture is lower than 6%. The final size can be controlled from 0.044mm to 0.125mm, which equal with that from 100 mesh to 325 mesh though Pendulum crusher.

Work principle of Raymond Mill:

Firstly, raw material is crushed by jaw crusher to the size required, then elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder evenly and continuously into the grinding chamber for powder-processing. The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between the ring and rollers to accomplish the grinding. After grinding, the rough materials will be recycled by the air from the fan back into the grinding chamber for regrinding and the fine powders are blew into the cyclone and poured out through the output-powder pipe as the final products.

Structural features of Raymond mill:

Firstly: It is the solid structure, cover small area; it is an independent producing system from primary material to the final powder.

Secondly: Fineness of the final powder is well-distributed, 99% of them can pass through the screen, and other milling machines are hard to approach.

Thirdly: Raymond mill commission equipment adopts closed gear case and pulley, stable convert and believable work.

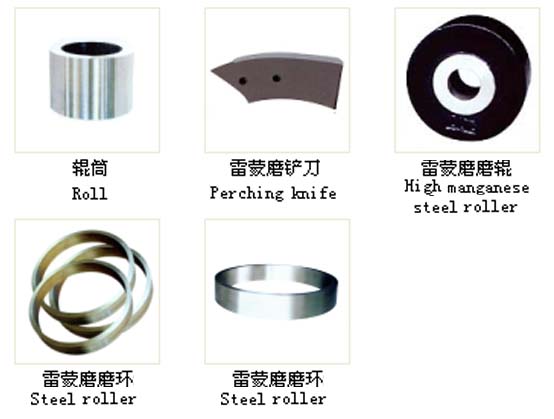

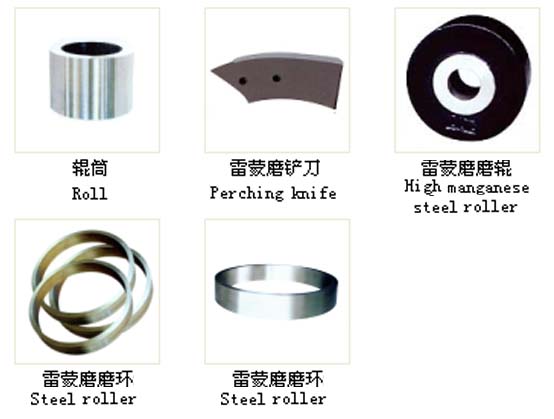

Fourthly: Important part adopt high quality steel, abrasion proof adopt high quality abrasion material, the whole machine have a high abrasion and have a believable work.

Fifthly: Its electric system adopt concentrating control, the workshop can realize no-people work and maintain, etc.

Work principle of Raymond Mill:

Firstly, raw material is crushed by jaw crusher to the size required, then elevated into a hopper from which the material is transported through the electro-magnetic vibrating feeder evenly and continuously into the grinding chamber for powder-processing. The rollers oscillate outward to press the ring because of the centrifugal force and the shovel scoops up the materials, send to the middle between the ring and rollers to accomplish the grinding. After grinding, the rough materials will be recycled by the air from the fan back into the grinding chamber for regrinding and the fine powders are blew into the cyclone and poured out through the output-powder pipe as the final products.

Structural features of Raymond mill:

Firstly: It is the solid structure, cover small area; it is an independent producing system from primary material to the final powder.

Secondly: Fineness of the final powder is well-distributed, 99% of them can pass through the screen, and other milling machines are hard to approach.

Thirdly: Raymond mill commission equipment adopts closed gear case and pulley, stable convert and believable work.

Fourthly: Important part adopt high quality steel, abrasion proof adopt high quality abrasion material, the whole machine have a high abrasion and have a believable work.

Fifthly: Its electric system adopt concentrating control, the workshop can realize no-people work and maintain, etc.

| Model |

Roller number (pcs) |

Roller size (mm) |

Inner dia. of roller(mm) |

Max. feed size(mm) |

Final size (mm) |

Capacity (t/h) |

Power (kw) |

Weight (t) |

Overall dimension (mm) |

| 3R1510 | 3 | 150*100 | 570*100 | 15 | 0.2-0.044 | 0.3-1.2 | 7.5 | 2 | 3200*2100*3800 |

| 3R2115 | 3 | 210*150 | 630*150 | 15 | 0.2-0.044 | 0.4-1.6 | 15 | 3.6 | 4500*2800*5800 |

| 3R2615 | 3 | 260*150 | 780*150 | 20 | 0.2-0.044 | 0.8-2.5 | 18.5 | 4.2 | 5650*3305*5950 |

| 3R2715 | 3 | 270*150 | 830*150 | 20 | 0.2-0.044 | 0.9-2.8 | 22 | 4.8 | 5600*3400*5900 |

| 3R3015 | 3 | 300*150 | 875*150 | 20 | 0.2-0.044 | 1.2-3.5 | 30 | 5.3 | 5700*3500*5900 |

| 4R3016 | 4 | 300*160 | 890*160 | 20 | 0.2-0.044 | 1.2-4 | 30 | 8.5 | 6500*4100*5200 |

| 4R3216 | 4 | 320*160 | 970*160 | 25 | 0.2-0.044 | 1.8-4.5 | 37 | 15 | 9900*5800*10580 |

| 5R4121 | 5 | 410*210 | 1280*210 | 30 | 0.2-0.044 | 3-9.5 | 75 | 24 | 7900*8000*9700 |

Get Price And Support

Simply complete the form below, click submit, you will get the price list and a representative will contact you within one business day. Please also feel free to contact us by email or phone.

Previous:Roller Press

FacebookOffers,corrpertitions&more

FacebookOffers,corrpertitions&more TwitterNews&conversation

TwitterNews&conversation LinkedinLink You& Me

LinkedinLink You& Me YoutubeLatest wdeos

YoutubeLatest wdeos