Product Search

Crusher Series

Home > Products > Crusher Series

High efficiency Fine Impact Crusher

Features: This series of crushers has been developed and improved by combining the advantages of the technology from both at home and abroad, so that the structural design has been further optimized. The features of rational combination design of three crushing chambers, novel adjusting mechanism, a

We're here to help

Easy ways to get the answers you need.

Contact Now

- TEL:0086-21-68406143-802

- FAX:0086-21- 68406146

- Email:[email protected]

Features:

This series of crushers has been developed and improved by combining the advantages of the technology from both at home and abroad, so that the structural design has been further optimized. The features of rational combination design of three crushing chambers, novel adjusting mechanism, and effective control of uniformity of the product fineness, easy access for maintenance have made the hammers and screen plates replaced more easily. All the wearing parts are made by new type of high alloy abrasion material with multiple elements so as to assure the abrasive property and impact-resisting property of hammers and lining plates. This series of crushers offers stable operation in an environment of low dust and less power consumption.

PCX High-efficiency Fine Impact Crushers are provided with five outstanding advantages as compared with conventional crushers:

1. High-efficient energy-saving: 40% power consumption reduced at equivalent output;

2. Super-fine Crushing capability: The newly added particle size adjusting mechanism has guaranteed the fineness of 85% of the particles at the discharge is controlled within 3mm;

3. New type of high quality alloy material with multiple V-Mo elements has made both ends of the tips detachable for use with ultra-long service life more than 4 times of the original life;

4. Short-stroke operation: Higher crushing ratio and Gr. I & Gr. II clinkers and Gr. II & Gr. III limes may be incorporated into Gr. I for crushing operation;

5. Easy in Maintenance: The rear cover of the upper machine box may be hydraulically (hand)-operated for replacing of the parts so as to facilitate maintenance.

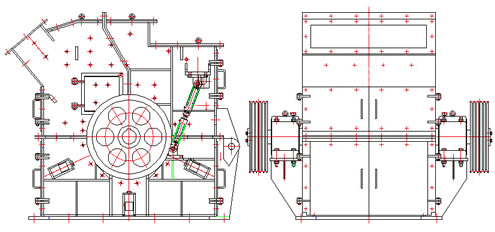

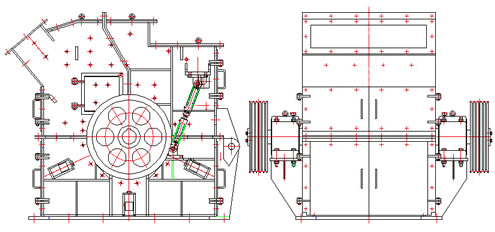

Structural Sketch

This series of crushers has been developed and improved by combining the advantages of the technology from both at home and abroad, so that the structural design has been further optimized. The features of rational combination design of three crushing chambers, novel adjusting mechanism, and effective control of uniformity of the product fineness, easy access for maintenance have made the hammers and screen plates replaced more easily. All the wearing parts are made by new type of high alloy abrasion material with multiple elements so as to assure the abrasive property and impact-resisting property of hammers and lining plates. This series of crushers offers stable operation in an environment of low dust and less power consumption.

PCX High-efficiency Fine Impact Crushers are provided with five outstanding advantages as compared with conventional crushers:

1. High-efficient energy-saving: 40% power consumption reduced at equivalent output;

2. Super-fine Crushing capability: The newly added particle size adjusting mechanism has guaranteed the fineness of 85% of the particles at the discharge is controlled within 3mm;

3. New type of high quality alloy material with multiple V-Mo elements has made both ends of the tips detachable for use with ultra-long service life more than 4 times of the original life;

4. Short-stroke operation: Higher crushing ratio and Gr. I & Gr. II clinkers and Gr. II & Gr. III limes may be incorporated into Gr. I for crushing operation;

5. Easy in Maintenance: The rear cover of the upper machine box may be hydraulically (hand)-operated for replacing of the parts so as to facilitate maintenance.

Structural Sketch

| Model |

Max. Feeding Size (mm) |

Average Discharge Size (mm) |

Capacity (t/h) |

Motor Power (kw) |

Weight (t) |

| PCX-800*300 | <60 | ≤5 (96%) | 20-25 | 37 | 2.5 |

| PCX-800*600 | <80 | ≤5 (94%) | 35-50 | 45 | 4.7 |

| PCX-800*800 | <100 | ≤5 (92%) | 40-60 | 75 | 6.5 |

| PCX-1000*1000 | <100 | ≤5 (91%) | 60-90 | 90 | 8.8 |

| PCX-1000*1200 | <100 | ≤5 (88%) | 75-110 | 110 | 13.6 |

| PCX-1300*1200 | <150 | ≤5 (86%) | 120-145 | 160 | 19.5 |

| PCX-1300*1400 | <200 | ≤5 (85%) | 145-180 | 180 | 26 |

Get Price And Support

Simply complete the form below, click submit, you will get the price list and a representative will contact you within one business day. Please also feel free to contact us by email or phone.

Previous:Hammer Crusher

Next:Roller Crusher

FacebookOffers,corrpertitions&more

FacebookOffers,corrpertitions&more TwitterNews&conversation

TwitterNews&conversation LinkedinLink You& Me

LinkedinLink You& Me YoutubeLatest wdeos

YoutubeLatest wdeos